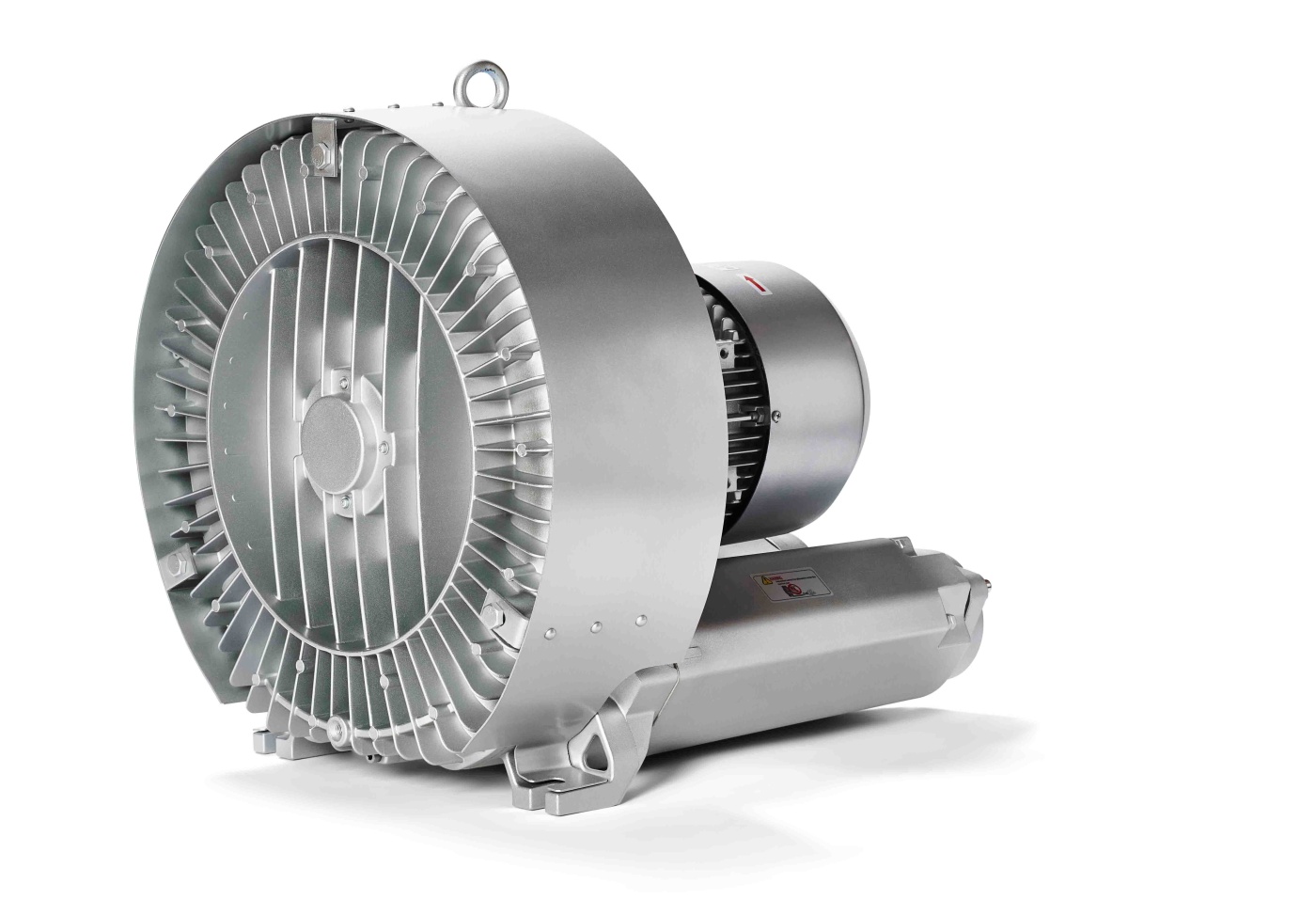

Zijkanaalventilatoren

Induvac levert een uitgebreid pakket zijkanaalventilatoren. De range begint bij 0,2 kW en eindigt bij 22 kW. Alle zijkanaal blowers worden gemaakt van giet aluminium, waarmee een hoge kwaliteit gegarandeerd wordt.De zijkanaalventilatoren zijn scherp geprijsd en direct leverbaar uit voorraad.

Kenmerkend voor de VACOM zijkanaalventilator zijn de eenvoud van de constructie, de betrouwbare werking en het minimale onderhoud.

Een betrouwbaar design

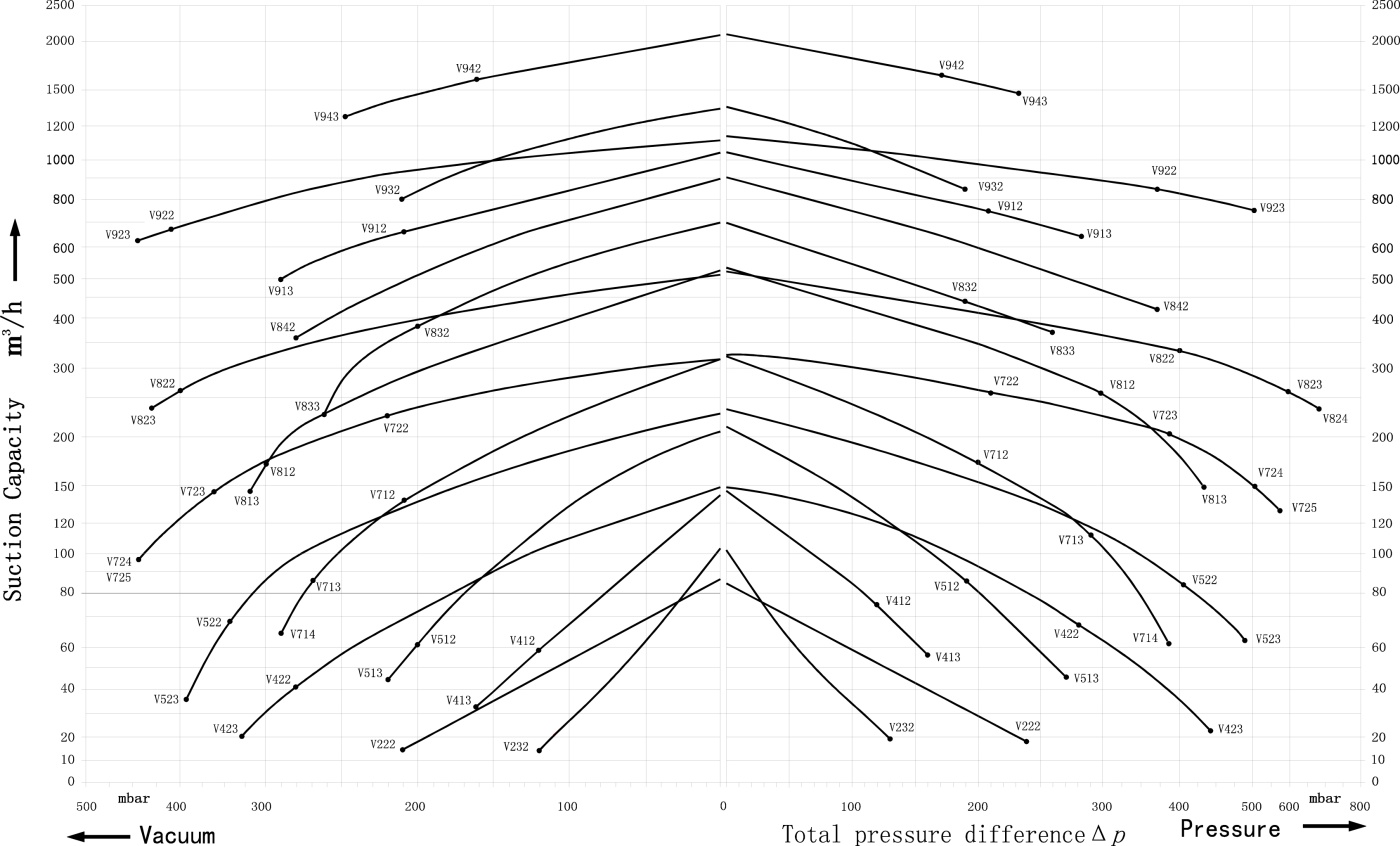

De standaard VACOM® zijkanaalventilatoren zijn opgebouwd uit een aluminium huis met concentrische waaier of rotor, waarbij de waaier direct op de motoras is gemonteerd. Deze waaier draait met een kleine speling contactvrij in het stator huis. De grotere modellen zijn uitgerust met een gietijzeren behuizing. De pomp wordt niet gesmeerd en er wordt dus absoluut olievrij een drukverschil gecreëerd (onder- of overdruk). Kenmerkend voor de VACOM® zijkanaalventilator zijn de eenvoud van de constructie, de betrouwbare werking en het minimale onderhoud. De lagering van de waaier is geïnstalleerd in het voordeksel van de zijkanaalventilator. Deze constructie garandeert een eenvoudige demontage en montage van de lagers. Met VACOM® zijkanaal-ventilatoren kunnen drukverschillen tot wel 700 mbar worden bereikt, met capaciteiten tot 2000 m3/u.

- Scherp geprijsd

- Direct leverbaar uit voorraad

- Geschikt voor (afwisselend) vacuüm en compressie

- Compacte, ruimtebesparende opbouw

- Drukverschillen van 0 tot 800 mbar

- Onderhoudsarm

- Stabiel en trillingsvrij

- Eenvoudige installatie

- Zeer laag geluidsniveau

- Horizontaal en verticaal te gebruiken

- Olievrije compressie dus geen verontreiniging van het medium

Anodiseren is een versneld elektrochemisch oxidatieproces dat de natuurlijke oxidehuid van aluminium versterkt. De transparante oxidelaag wordt hierdoor aanzienlijk dikker dan de natuurlijke oxidefilm. Hierdoor krijgt het aluminium een sterke corrosieweerstand en langdurige bescherming. En dankzij de transparante laag blijft het metaalkarakter behouden. Alle zijkanaalventilatoren van Induvac kunnen geleverd worden in een geanodieerde versie. De zijkanaalventilatoren zijn dan beter bestand tegen omgevingsinvloeden, zoals vochtige- of agressieve dampen, zee lucht, reinigingsmiddelen, etc. Neem contact met ons op om de mogelijkheden door te spreken.

ENKELTRAPS ZIJKANAALVENTILATOREN 3 FASE

| Type | Vermogen | Capaciteit | Onderdruk | Overdruk | ||

| kW | m³/uur | mbar | mbar | |||

| VC 302-010 |

|

0,2 | 55 | 80 | 90 | |

| VC 304-230 |

|

0,4 | 105 | 120 | 130 | |

| VC 307-410 |

|

0,75 | 145 | 160 | 150 | |

| VC 311-510 | 1,1 | 210 | 150 | 150 | ||

| VC 315-510 |

|

1,5 | 210 | 230 | 220 | |

| VC 322-510 |

|

2,2 | 210 | 250 | 310 | |

| VC 322-710 |

|

2,2 | 318 | 200 | 190 | |

| VC 322-730 |

|

2,2 | 420 | 160 | 150 | |

| VC 330-710 |

|

3,0 | 318 | 280 | 280 | |

| VC 330-730 |

|

3,0 | 420 | 240 | 230 | |

| VC 340-710 |

|

4,0 | 318 | 290 | 350 | |

| VC 340-730 |

|

4,0 | 420 | 260 | 290 | |

| VC 340-810 |

|

4,0 | 530 | 200 | 180 | |

| VC 355-810 |

|

5,5 | 530 | 300 | 300 | |

| VC 355-830 |

|

5,5 | 700 | 220 | 220 | |

| VC 375-810 |

|

7,5 | 530 | 340 | 420 | |

| VC 375-830 |

|

7,5 | 700 | 300 | 320 | |

| VC 375-910 |

|

8,5 | 1050 | 200 | 190 | |

| VC 311-910 |

|

12,5 | 1050 | 260 | 290 | |

| VC 311-930 |

|

12,5 | 1370 | 210 | 200 | |

| VC 315-943 |

|

15,0 | 2050 | 190 | 170 | |

| VC 318-910 | 18,5 | 1050 | 350 | 500 | ||

| VC 318-943 |

|

18,5 | 2050 | 260 | 240 |

DUBBELTRAPS ZIJKANAALVENTILATOREN 3 FASE

| Type | Vermogen | Capaciteit | onderdruk | overdruk | ||

| kW | m³/uur | mbar | mbar | |||

| VC 305-220 |

|

0,55 | 85 | 200 | 200 | |

| VC 307-220 |

|

0,7 | 85 | 210 | 240 | |

| VC 311-320 |

|

1,3 | 110 | 280 | 290 | |

| VC 315-420 |

|

1,5 | 150 | 320 | 310 | |

| VC 322-420 |

|

2,2 | 150 | 320 | 420 | |

| VC 322-720 | 2,2 | 320 | 220 | 210 | ||

| VC 330-520 |

|

3,0 | 230 | 380 | 450 | |

| VC 340-520 |

|

4,0 | 230 | 390 | 500 | |

| VC 340-720 |

|

4,0 | 320 | 400 | 370 | |

| VC 355-720 |

|

5,5 | 320 | 420 | 530 | |

| VC 375-720 |

|

7,5 | 320 | 420 | 610 | |

| VC 375-820 |

|

7,5 | 520 | 380 | 360 | |

| VC 311-820 |

|

11,0 | 520 | 460 | 570 | |

| VC 311-840 |

|

11,0 | 900 | 280 | 370 | |

| VC 315-920 |

|

15,0 | 1110 | 410 | 370 | |

| VC 318-920 | 18,5 | 1110 | 440 | 490 | ||

| VC 318-940 |

|

18,5 | 1940 | 240 | 210 |

DUBBELTRAPS ZIJKANAALVENTILATOREN HOGE DRUK

| Type | Vermogen | Capaciteit | Onderdruk | Overdruk | |

| kW | m³/uur | mbar | mbar | ||

| VC 305-214 | 0,55 | 47 | 230 | 290 | |

| VC 315-224 | 1,5 | 47 | 370 | 650 | |

| VC 305-314 | 0,55 | 66 | 250 | 250 | |

| VC 308-314 | 0,81 | 66 | 280 | 350 | |

| VC 315-324 | 1,5 | 65 | 440 | 540 | |

| VC 311-414 | 1,1 | 87 | 300 | 380 | |

| VC 315-424 | 1,5 | 87 | 480 | 450 | |

| VC 333-424 | 3,3 | 87 | 500 | 750 | |

| VC 340-524 | 4,0 | 120 | 500 | 820 | |

| VC 315-553 | 15,0 | 480 | 610 | 830 |

ENKELTRAPS ZIJKANAALVENTILATOREN 1 FASE

| Type | Vermogen | Capaciteit | Onderdruk | Overdruk | |

| kW | m³/uur | mbar | mbar | ||

| VC 102-010 | 0,2 | 55 | 70 | 80 | |

| VC 104-230 | 0,37 | 100 | 110 | 110 | |

| VC 108-410 | 0,80 | 145 | 150 | 160 | |

| VC 111-430 | 1,1 | 180 | 170 | 210 | |

| VC 115-510 | 1,5 | 210 | 190 | 200 | |

| VC 122-710 | 2,2 | 318 | 190 | 190 |

DUBBELTRAPS ZIJKANAALVENTILATOREN 1 FASE

| Type | Vermogen | Capaciteit | Onderdruk | Overdruk | ||

| kW | m³/uur | mbar | mbar | |||

| VC 107-220 |

|

0,7 | 88 | 210 | 240 | |

| VC 111-320 |

|

1,1 | 120 | 240 | 280 | |

| VC 115-420 |

|

1,5 | 150 | 280 | 290 |

ACCESSOIRES

| Type | Omschrijving | ||

| VCF |

|

Aanzuigfilter (in-line) | |

| VCFT |

|

Aanzuigfilter | |

| DB |

|

Drukbeveiliging | |

| EGD |

|

Geluidsdemper |